Equipment and Main Process

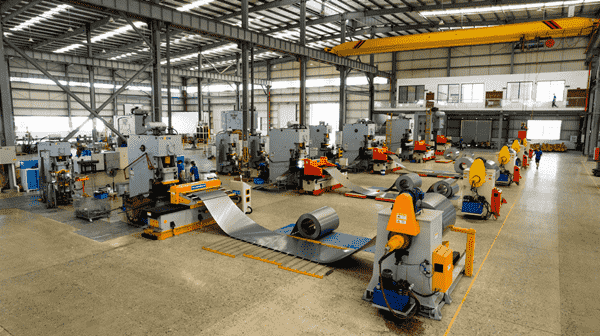

Punching Workshop

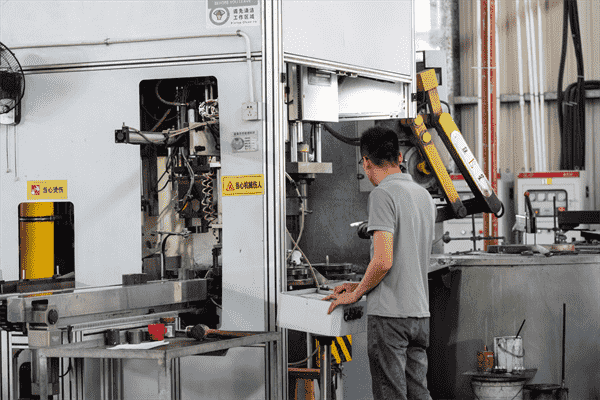

Rotor Die Casting Workshop

Rotor die casting workshop at Widetec

Winding Workshop

The winding workshop includes:

– Manual winding, which is flexible and is suitable for the orders with few quantity but many models, such as distributors.

– Semi-automatic winding line. which is suitable for the orders with large quantity and few models, reducing costs and ensuring production efficiency.

Vacuum Pressure Impregnated Workshop

Vaccum Pressure Impregnated (VPI) process can eliminate corona and promote insulation longevity.

Ultrasonic Cleaning

Ultrasonic cleaning can remove the oil and dust on the components, and ensure the adhesion of the painiting.

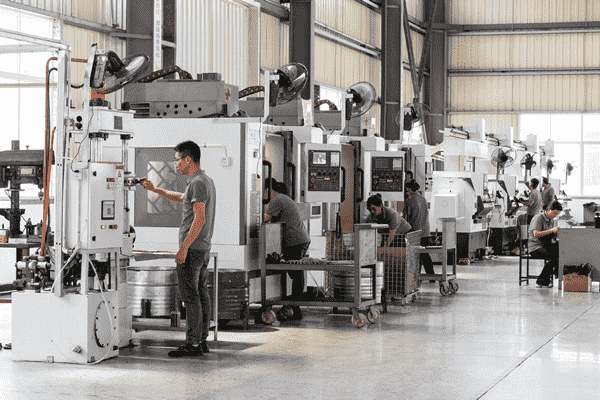

Machining Workshop

– Traditional CNC machines, such as lathes, multi-spindle drilling and tapping machine, milling machine, machining centre, etc, which is flexible and is suitable for the orders with few quantity but large models, such as distributors.

– Automatic machining line, which is suitable for the orders with many quantity and few models, reducing costs and ensuring production efficiency.

Painting Workshop

Including painting and electrostatic powder coating.

Assembly and Packing

Including:

– Semi-automatic assembly line, every worker is always operate the same process, repeating the same action hundreds of times every day, which ensures they can not make any mistakes.

– Traditional assembly line, which is suitable for the customers with many models and few quantity, such as distributors. The flexible production mode ensures they can switch different models in a very short time