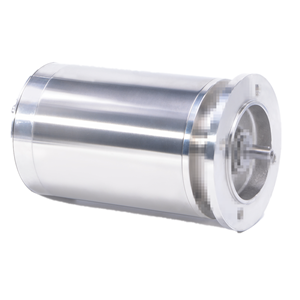

IP69K MOTORS -

STAINLESS STEEL-

TENV

Stainless steel Motors for food processing, pharmaceutical and other applications requiring extreme cleanliness and frequent washdowns

When food, beverage or pharmaceutical production plants are washed down, the motors – along with other parts – are often subjected to high pressure water jets (sometimes at high temperatures) or even more aggressive cleaning agents.

The motor is TENV(totally enclosed non ventilated).

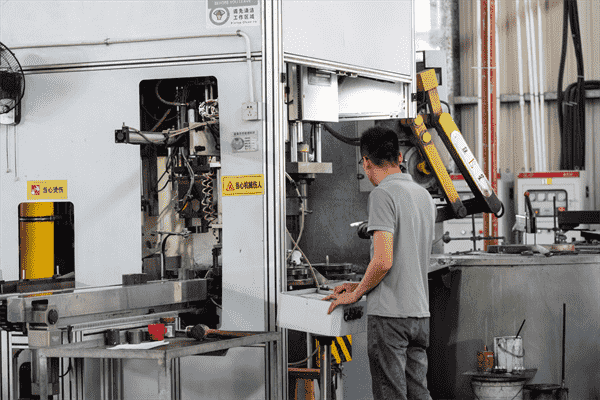

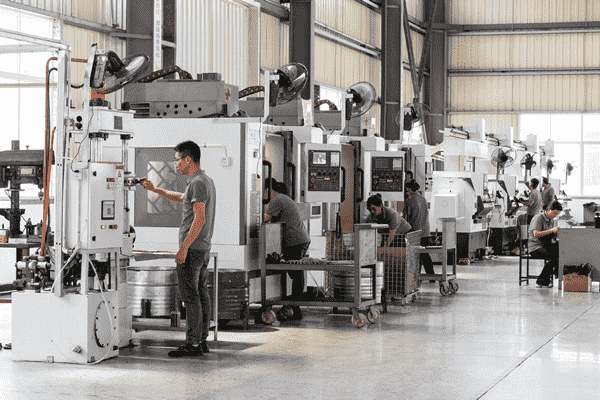

Factory Video

1989

Years of Establish

500+

Employees

30

Engineers

55

Numbers of Patents

130,000

Company Area

170+

Inspection Process

20

Well Known Customers

500+

Satisfied Customers

Product Range

Standard

IEC / NEMA

Phase

Three Phase

Insulation Class

F

Material of Frame

AISI 304, 316L

IP Degree

IP69K

Enclosure

TENV

Certification

CE, CSA

Efficiency

IE3/IE4

Voltage / Frequency

230/400V, 50HZ

277/480V, 60HZ

208-230/460V, 60HZ

575V, 60HZ

Frame Size

56-100(IEC)

56C(NEMA)

Speed

3000/1500/1000/750 rpm (50HZ)

3600 / 1800/1200/900rpm (60HZ)

Power Range

0.06-2.2kW

0.08-3hp

Standard Features

For round body motor

- No cooling fins, complete smooth surface

- No paint to chip or flake and no surface that will rust

- Rating plate is engraved on the outer Non Drive End cover to reduce areas where bacteria can lurk

- The ss grade shaft mitigates unwanted magnetic flux

- “INVERTER DUTY OPERATION” – 4:1 Constant Torque (CT) / 10:1 Variable Torque (VT)

- Hygienic Cable Gland Certified by European Hygienic Engineering and Design Group

- Completely Smooth Surfaces Guarantee the Highest Needs on Ultra-hygienic Clean Lines

- Thanks to the low losses electromagnetic design and excellent process, the surface temperature of motor is low enough, nobody will be scalded by the hot motor

- Brake, encoder, PTO Thermal Protector is Available

For welded terminal box motor:

- Wide terminal box – easy installation

- Leading wires are potted by hygienic epoxy, which can prevent water from getting into the motor

- Condensation could be easily drained by removing the drain caps at both Drive End and Non Drive End sides, you even don’t need to remove the fan cowl

- Nameplate Laser Printed on the Back Cover

- Terminal box at NDE side, easy Connection, with Waterproof Butt Connector

Don't Hesitate To Contact Us Now!

Group Structure

Huifeng Motors Co.,Ltd.

Huifeng is the parent company and provides financial and technical support to the other three companies.

Xiamen HFM Electric Co.,Ltd.

HFM is equipped with the most advanced semi-automatic processing equipment, which has the advantage of producing products with large procurement volume and single model.

Widetec Machinery Manufacturing Co.,Ltd.

Widetec mainly carries out high-speed stampping and rotor automatic die casting, which improves the problem of difficult recruitment in previous high pollution processes.

WM Motors srl(Italy)

WM introduced advanced European design technology and manufacturing technology to Huifeng and established its own brand in Europe.

What Our Customers Say

Huifeng is different. He really knows what we need, he is working with us to create motor solutions and solve our problems.

Jemma Stone

We have been cooperating with Huifeng for many years, and we have never had any complaints about him

Kelly Joe

One customer told me that he bought a motor from us which was made by Huifeng 20 years ago, and now the motor is still working well!

Samantha Gilbert

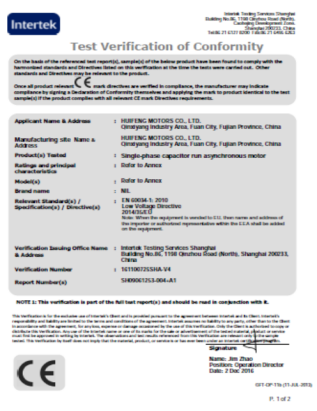

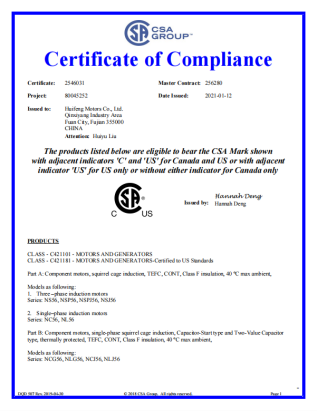

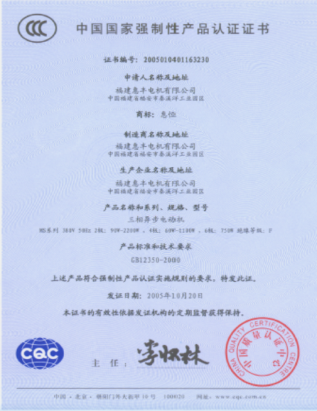

Certificate

CE(Intertek)

CSA(CSA Group)

CCC(CQC)

ISO9001

Similar Products

Request Info

As a professional electric motor manufacturer in China, We have been in the electric motor industry for over 30 years.

Whether you need:

AC or permanent magnet electric motors

CNC machining service or stator and rotor laminations

High pressure blower

Standard motors or custom motors

Just contact us, Huifeng can always satisfy your different needs.