European Quality & Chinese Price

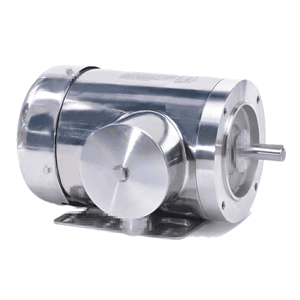

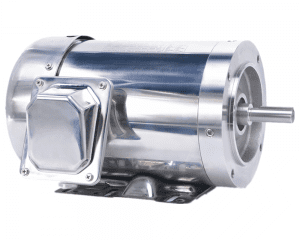

Stainless Steel AC Motor Manufacturer

Feel the Difference

Export to Europe & North America Since 1989

1989

Years of Establish

500+

Employees

30

Engineers

55

Numbers of Patents

130,000

Company Area

170+

Inspection Process

20

Well Known Customers

500+

Satisfied Customers

Stainless Steel Washdown Motor Manufacturer

Huifeng is a Leading Stainless Steel Motor Manufacturer Since 1989, Export to Europe & North American, Strict EU & CE & ISO & CSA compliance.

Stainless Steel Motor For Poultry Applications

Stop Motor Failures from Blood, Bones & Pressure Washing!

When motors fail in poultry plants, YOU deal with:

- Costly shutdowns for motor replacements

- Angry customers blaming YOUR equipment

- Lost profits from wasted chicken & downtime

How Huifeng Solves Poultry-Specific Problems:

1.Problem: Bones Break Motors Sealing and Cause Motor Burns

Shredded bones get into seals. Motors locked or water getting into the motors, so motors burn out.

Our Fix: Bone-Proof Seals

Unique seal design blocks bone chips

- Sealed bearings keep blood/fat/bones out of motor core

→ No more motor jams. Less breakdowns for your customers. - → *Zero bone-jam failures in 2 years of testing.*

- Sealed bearings keep blood/fat/bones out of motor core

2.Problem: Blood & Fat Trap in Flanges

Standard flanges collect gunk. Bacteria grows. Cleaning takes hours.

Our Fix: 4-Channel Open Flange Design

- when the motor mounted shaft up, 4 deep grooves wash out guts/blood FAST

Flat stainless steel – nothing sticks

→ *Cleans 70% faster – no tools needed.*

3.Problem: Daily Corrosive Washes Kill Motors

High-pressure hot water + chemicals rust motors fast.

Our Fix: IP69K Armor

Full stainless steel body (316L)

IP69K certified – survives 80°C pressure washes daily

Laser-etched labels won’t wash off

→ Lasts 3X longer than standard motors.

Get Motors That Outlast the Toughest Lines:

✅ 30% less downtime for your customers

✅ Zero bone-jam failures in field tests

Related Products:

Stainless Steel Motor For Food Applications

Solve Costly Line Stops & Inspection Fails

When cheap motors fail, YOU pay:

→ Spoiled batches & angry customers

→ FDA/EHEDG audit failures & fines

→ Costly motor swaps & labor headaches

Food Plant Problems & Huifeng Fixes:

- Problem: Toxic Motors Poison Food

Flaking paint or cheap metal dust contaminates products → recalls!

✅ Fix: Safe-Contact DesignPure 304/316L stainless steel – zero paint, zero flakes

Food-grade FKM seals – resists oils/acid, won’t degrade

Laser-etched nameplate – no stickers or grooves to trap dirt

2. Problem: Washdown Water Kills Motors

Daily pressure washing drowns standard motors.

✅ Fix: IP69K Insulation Class

Waterproof seal – survive under high pressure steam jet and aggressive cleaning agents

- FKM rubber seals resist heat/chemicals

3. Problem: Speed Changes Burn Windings

Conveyor/pump speed shifts overheat motors.

✅ Fix: VFD Muscle

10:1 VT / 4:1 CT – loves speed changes

Cool surface (<65°C) – safe to touch

4. Problem: Bateria Contaminate Food

Gaps allow grease/dirt inside → recall risk.

✅ Fix: Double-Lock Seals

Totally smooth motor body design block dirts

Hygienic design cable gland from Germany– won’t corrode

5. Problem: Custom Brackets Waste $$

Odd-sized motors need expensive adapters.

✅ Fix: Gearbox-Ready Fit

Standard IEC B14/B5, and NEMA 56C 143/5TC, 182/4TC flanges

Bolts to gearboxes in 10 minutes

Proven in Food Battles:

✅ 0% material contamination in 5 years

✅ Laser-etched labels survive 200°C steam

✅ 12-months no-leak, no-flake warranty

Related Products:

Stainless Steel Motor For Beverage Applications

Huifeng Stainless Steel Motors: Beat Sticky, Acidic Nightmares

When motors die in juice plants:

→ You lose cash replacing burnt motors

→ Lines halt – thousands of liters spoil

→ Customers scream about delivery delays

How We Crush Beverage Plant Problems:

Problem: Sticky Syrup Murders Motors

Sugar sludge jams fans + overheats windings.

Our Fix: Non-Stick ArmorLaser-smooth shell (Ra<0.4μm) – syrup slides off

IP69K sealed – pressure wash gunk away

→ *Zero sugar-jam failures in 18 months*

Problem: Acid Attacks Eat Motors

Citric acid + hot washes rot metal fast.

Our Fix: Acid-Proof Tank316L stainless steel laughs at lemon/orange acid

Triple-sealed joints block liquid invasion

→ Lasts 4X longer in OJ plants

Problem: Speed Shifts Burn Bearings

Pulp density changes strain motors → burnout.

Our Fix: Smart VFD Muscle10:1 VT / 4:1 CT – handles speed changes smoothly

Cool-run design (<65°C surface)

→ No more bearing meltdowns

Problem: Custom Mounts Wreck Timelines

Odd-sized motors delay machine assembly.

Our Fix: Gearbox-Ready FitStandard IEC/B5 flange – bolts to pumps/gearboxes in 15 mins

Same size as ABB/WEG motors → swap in 1 hour

→ Slash install time by 70%

Related Products:

Stainless Steel Motor For Seashore Applications

Laugh at Salt, Waves & Corrosion

Failing motors on boats/ships cost YOU:

→ Costly dry-dock repairs ($10k+/day)

→ Stranded vessels & cargo delays

→ Safety risks in rough seas

Ocean Problems & Huifeng Fixes:

Problem: Saltwater Eats Motors

Salt spray turns aluminum motor and cast iron motor into Swiss cheese in months.

✅ Fix: 304/316L Sea ArmorMarine-grade 304/316L steel – ignores salt corrosion

Laser-etched labels – won’t wash away

Problem: Waves Drown Bearings

Splash, spray & humidity rust bearings fast.

✅ Fix: IP56/IP69K Deep-SealWaterproof seals – block waves/spray

FKM rubber seal – resists seawaterProblem: Humidity Fries Electronics

Problem: Humidity Fries Electronics

100% humidity cooks windings → short circuits.

✅ Fix: Humidity Warrior

Salt-proof windings – resist moisture

Cool surface (<75°C) – prevents condensation

Problem: Custom Fits Sink Timelines

Odd-sized motors need weeks of adapters.

✅ Fix: Direct-Drive FitStandard NEMA/IEC flanges – bolts to pumps/winches in 15 mins

Fits most marine gearboxes → no custom work

Related Products:

Don't Hesitate To Contact Us Now!

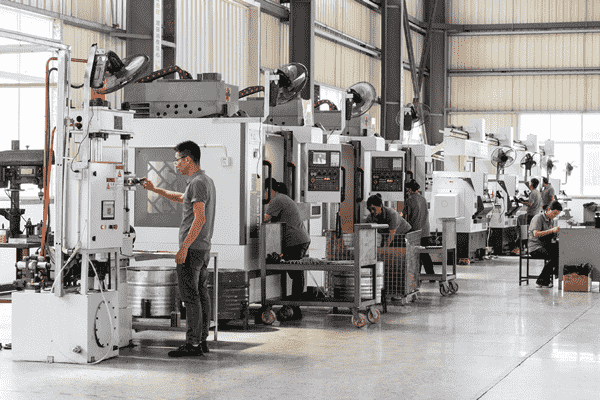

Factory Video

WHO IS HUIFENG

As a leading Chinese manufacturer of AC motors and permanent magnet motors since 1989. Its products are mainly sold in Europe, North America, and Australia.

Premium motors = fewer replacements = less down time.

Use Huifeng’s motor, means you can buy European standard motor with Chinese price!

Group Structure

Huifeng Motors Co.,Ltd.

Huifeng is the parent company and provides financial and technical support to the other three companies.

Xiamen HFM Electric Co.,Ltd.

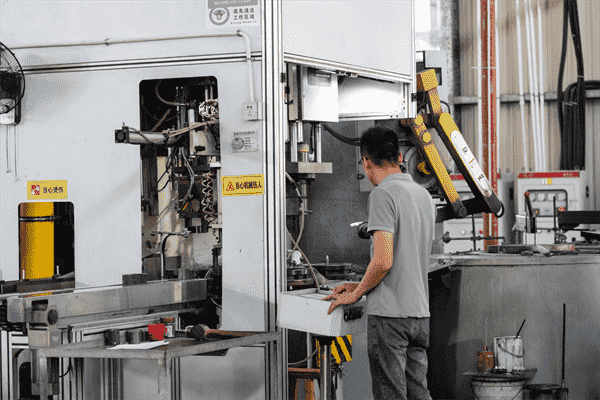

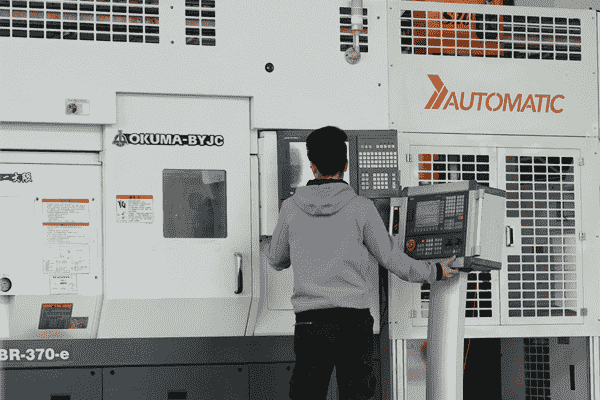

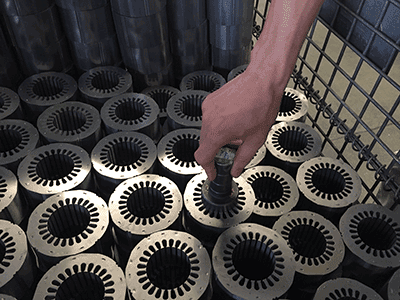

HFM is equipped with the most advanced semi-automatic processing equipment, which has the advantage of producing products with large procurement volume and single model.

Widetec Machinery Manufacturing Co.,Ltd.

Widetec mainly carries out high-speed stampping and rotor automatic die casting, which improves the problem of difficult recruitment in previous high pollution processes.

WM Motors srl(Italy)

WM introduced advanced European design technology and manufacturing technology to Huifeng and established its own brand in Europe.

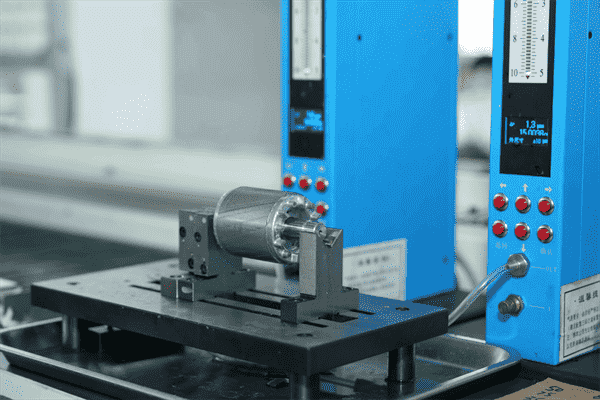

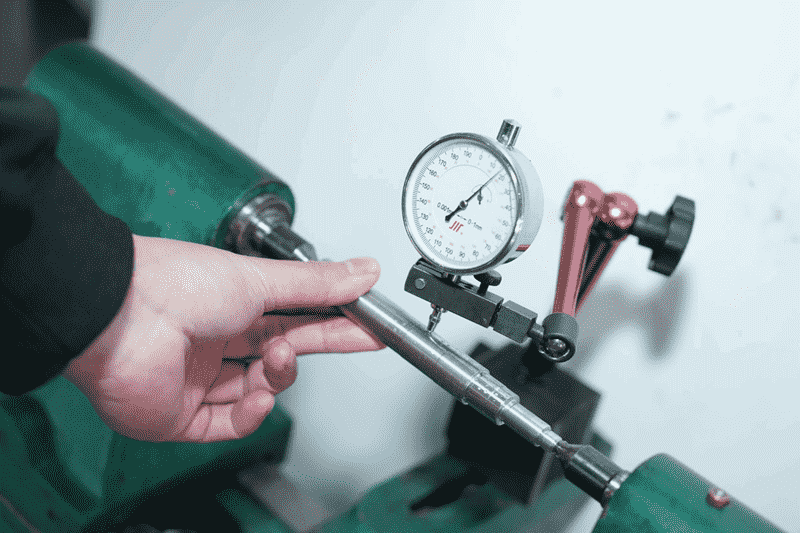

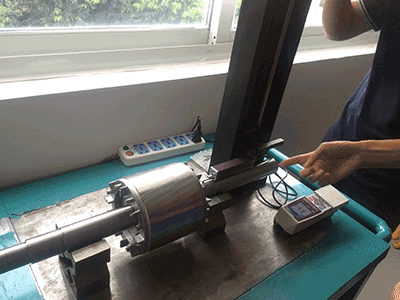

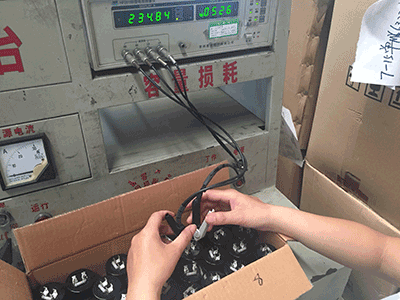

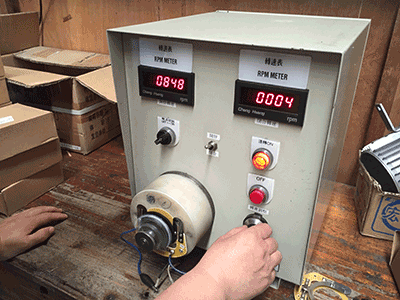

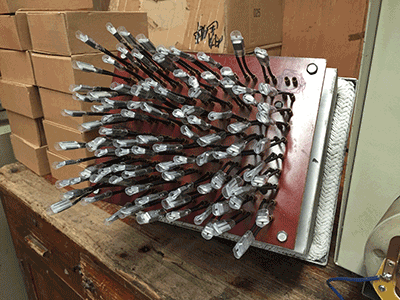

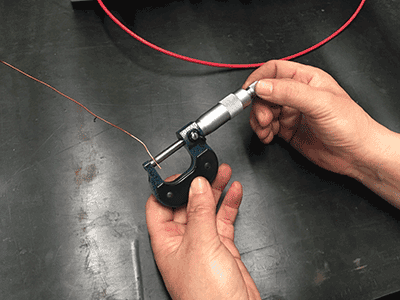

Inspection

What Our Customers Say

Huifeng is different. He really knows what we need, he is working with us to create motor solutions and solve our problems.

Chief Engineer at a Top 10 Motor Company

We have been cooperating with Huifeng for many years, and we have never had any complaints about him

Purchase Manager at a Global Fan Manufacturer

One customer told me that he bought a motor from us which was made by Huifeng 20 years ago, and now the motor is still working well!

CEO at a Leading Gearbox Company

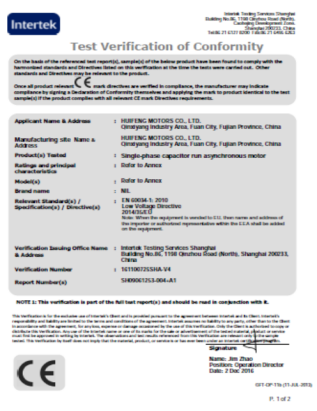

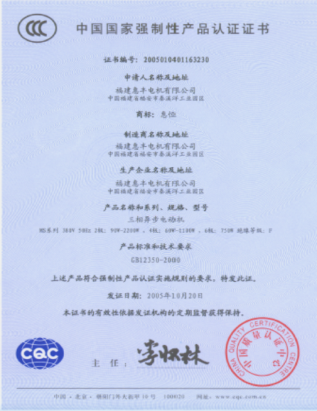

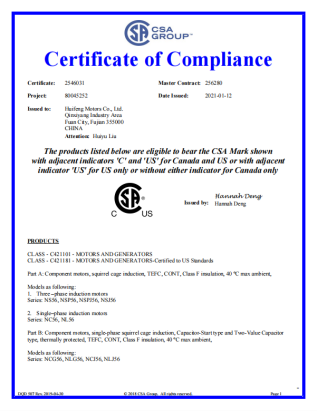

Certificate by Top Institutions, Minimized Your Risk

Our motors meet the highest global safety and quality standards, verified by multiple top certifications (including Intertek, TUV, CQC).

These leading agencies conduct strict, unannounced factory audits – up to 4 times yearly, so that the factories to face their inspections in their most realistic condition, not all factories pass.

This ensures our products are always made under real production conditions, giving you confidence in their safety and performance.

CE(Intertek)

CCC(CQC)

CSA(CSA Group)

ISO9001

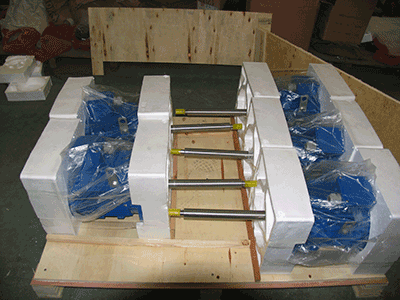

Packing

We have different types of packages for air shipment and ocean shipment.

Delivery

Request Info

As a professional stainless steel washdown electric motor manufacturer in China, We have been in the electric motor industry for over 30 years.

Whether you need:

AC or permanent magnet electric motors

CNC machining service or stator and rotor laminations

Turbo blower

Standard motors or custom motors

Just contact us, Huifeng can always satisfy your different needs.