1989

成立时间

500+

员工

30

工程师

55

专利数

130,000

公司面积

170+

检验项目

20

世界知名客户

500+

十分满意客户

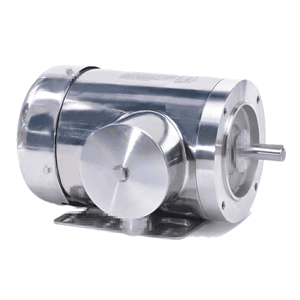

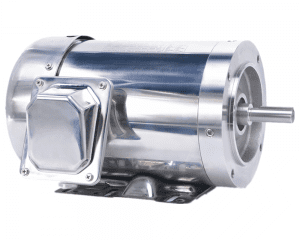

不锈钢可冲洗电机制造商

惠丰是专业的不锈钢电机制造商,自1989年成立以来,电机出口欧洲、北美,产品严格按照欧盟 & CE & ISO & CSA标准

家禽处理设备用不锈钢电机

Stop Motor Failures from Blood, Bones & Pressure Washing!

When motors fail in poultry plants, YOU deal with:

- Costly shutdowns for motor replacements

- Angry customers blaming YOUR equipment

- Lost profits from wasted chicken & downtime

How Huifeng Solves Poultry-Specific Problems:

1.Problem: Bones Break Motors Sealing and Cause Motor Burns

Shredded bones get into seals. Motors locked or water getting into the motors, so motors burn out.

Our Fix: Bone-Proof Seals

Unique seal design blocks bone chips

- Sealed bearings keep blood/fat/bones out of motor core

→ No more motor jams. Less breakdowns for your customers. - → *Zero bone-jam failures in 2 years of testing.*

- Sealed bearings keep blood/fat/bones out of motor core

2.Problem: Blood & Fat Trap in Flanges

Standard flanges collect gunk. Bacteria grows. Cleaning takes hours.

Our Fix: 4-Channel Open Flange Design

- when the motor mounted shaft up, 4 deep grooves wash out guts/blood FAST

Flat stainless steel – nothing sticks

→ *Cleans 70% faster – no tools needed.*

3.Problem: Daily Corrosive Washes Kill Motors

High-pressure hot water + chemicals rust motors fast.

Our Fix: IP69K Armor

Full stainless steel body (316L)

IP69K certified – survives 80°C pressure washes daily

Laser-etched labels won’t wash off

→ Lasts 3X longer than standard motors.

Get Motors That Outlast the Toughest Lines:

✅ 30% less downtime for your customers

✅ Zero bone-jam failures in field tests

Related Products:

食品处理设备用不锈钢电机

Solve Costly Line Stops & Inspection Fails

When cheap motors fail, YOU pay:

→ Spoiled batches & angry customers

→ FDA/EHEDG audit failures & fines

→ Costly motor swaps & labor headaches

Food Plant Problems & Huifeng Fixes:

- Problem: Toxic Motors Poison Food

Flaking paint or cheap metal dust contaminates products → recalls!

✅ Fix: Safe-Contact DesignPure 304/316L stainless steel – zero paint, zero flakes

Food-grade FKM seals – resists oils/acid, won’t degrade

Laser-etched nameplate – no stickers or grooves to trap dirt

2. Problem: Washdown Water Kills Motors

Daily pressure washing drowns standard motors.

✅ Fix: IP69K Insulation Class

Waterproof seal – survive under high pressure steam jet and aggressive cleaning agents

- FKM rubber seals resist heat/chemicals

3. Problem: Speed Changes Burn Windings

Conveyor/pump speed shifts overheat motors.

✅ Fix: VFD Muscle

10:1 VT / 4:1 CT – loves speed changes

Cool surface (<65°C) – safe to touch

4. Problem: Bateria Contaminate Food

Gaps allow grease/dirt inside → recall risk.

✅ Fix: Double-Lock Seals

Totally smooth motor body design block dirts

Hygienic design cable gland from Germany– won’t corrode

5. Problem: Custom Brackets Waste $$

Odd-sized motors need expensive adapters.

✅ Fix: Gearbox-Ready Fit

Standard IEC B14/B5, and NEMA 56C 143/5TC, 182/4TC flanges

Bolts to gearboxes in 10 minutes

Proven in Food Battles:

✅ 0% material contamination in 5 years

✅ Laser-etched labels survive 200°C steam

✅ 12-months no-leak, no-flake warranty

Related Products:

果汁设备用不锈钢电机

Huifeng Stainless Steel Motors: Beat Sticky, Acidic Nightmares

When motors die in juice plants:

→ You lose cash replacing burnt motors

→ Lines halt – thousands of liters spoil

→ Customers scream about delivery delays

How We Crush Beverage Plant Problems:

Problem: Sticky Syrup Murders Motors

Sugar sludge jams fans + overheats windings.

Our Fix: Non-Stick ArmorLaser-smooth shell (Ra<0.4μm) – syrup slides off

IP69K sealed – pressure wash gunk away

→ *Zero sugar-jam failures in 18 months*

Problem: Acid Attacks Eat Motors

Citric acid + hot washes rot metal fast.

Our Fix: Acid-Proof Tank316L stainless steel laughs at lemon/orange acid

Triple-sealed joints block liquid invasion

→ Lasts 4X longer in OJ plants

Problem: Speed Shifts Burn Bearings

Pulp density changes strain motors → burnout.

Our Fix: Smart VFD Muscle10:1 VT / 4:1 CT – handles speed changes smoothly

Cool-run design (<65°C surface)

→ No more bearing meltdowns

Problem: Custom Mounts Wreck Timelines

Odd-sized motors delay machine assembly.

Our Fix: Gearbox-Ready FitStandard IEC/B5 flange – bolts to pumps/gearboxes in 15 mins

Same size as ABB/WEG motors → swap in 1 hour

→ Slash install time by 70%

Related Products:

海鲜处理设备用不锈钢电机

Laugh at Salt, Waves & Corrosion

Failing motors on boats/ships cost YOU:

→ Costly dry-dock repairs ($10k+/day)

→ Stranded vessels & cargo delays

→ Safety risks in rough seas

Ocean Problems & Huifeng Fixes:

Problem: Saltwater Eats Motors

Salt spray turns aluminum motor and cast iron motor into Swiss cheese in months.

✅ Fix: 304/316L Sea ArmorMarine-grade 304/316L steel – ignores salt corrosion

Laser-etched labels – won’t wash away

Problem: Waves Drown Bearings

Splash, spray & humidity rust bearings fast.

✅ Fix: IP56/IP69K Deep-SealWaterproof seals – block waves/spray

FKM rubber seal – resists seawaterProblem: Humidity Fries Electronics

Problem: Humidity Fries Electronics

100% humidity cooks windings → short circuits.

✅ Fix: Humidity Warrior

Salt-proof windings – resist moisture

Cool surface (<75°C) – prevents condensation

Problem: Custom Fits Sink Timelines

Odd-sized motors need weeks of adapters.

✅ Fix: Direct-Drive FitStandard NEMA/IEC flanges – bolts to pumps/winches in 15 mins

Fits most marine gearboxes → no custom work

Related Products:

不要犹豫,马上联系我们!

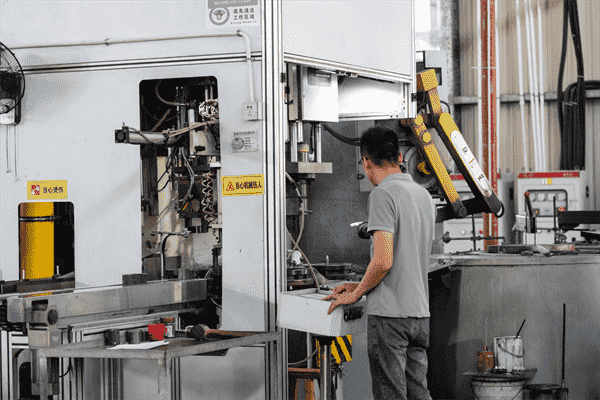

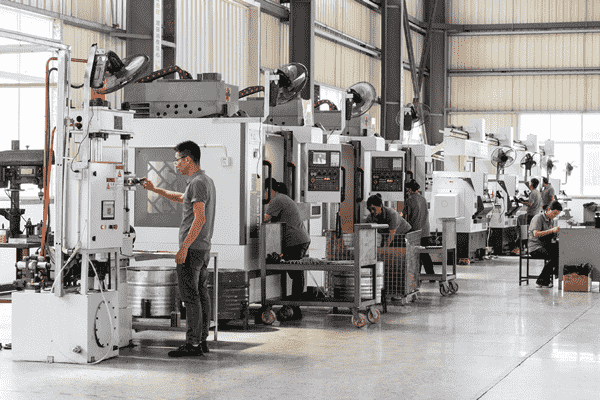

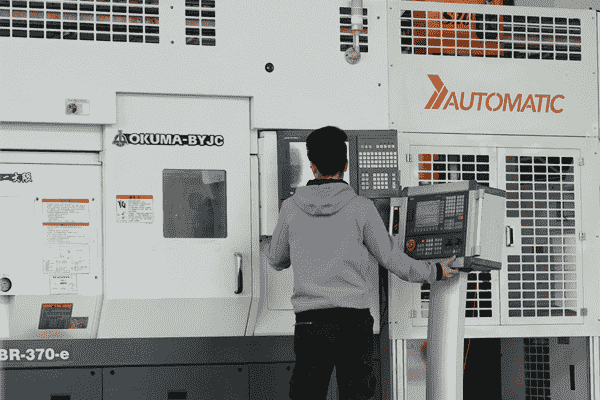

工厂视频

走近惠丰

公司结构

福建惠丰电机有限公司

惠丰是母公司,并为其他公司提供支持

厦门惠禾盛电气有限公司

惠禾盛配备最先进的自动、半自动生产设备,适合为批量大、型号单一的客户服务

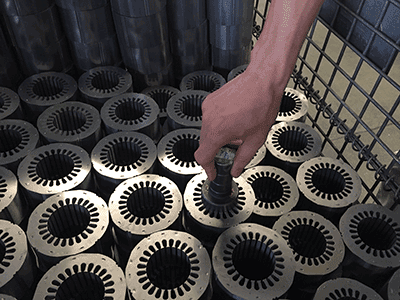

福建惠德机械制造有限公司

惠德主要生产定转子冲片、转子压铸等工序,同时也能进行数控加工和电机生产

WM Motors srl(意大利)

WM引进了欧洲先进的设计和工艺,并在欧洲建立起自己的品牌

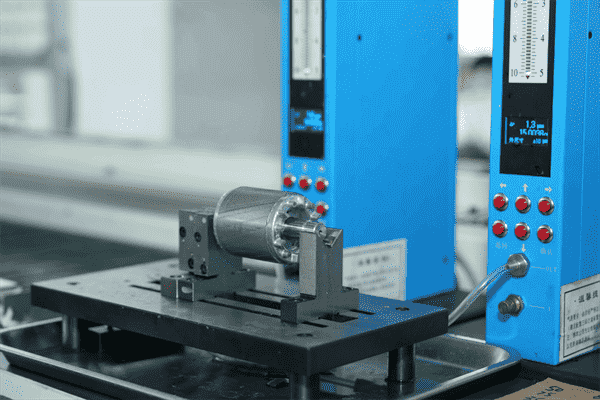

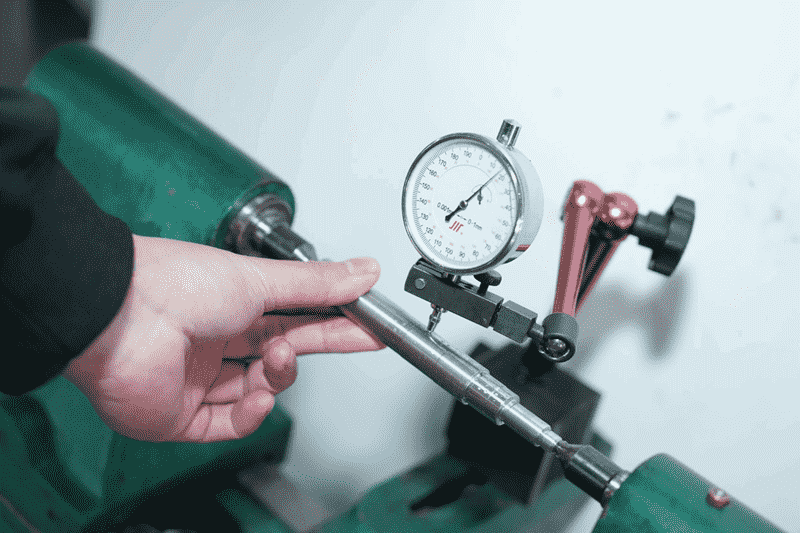

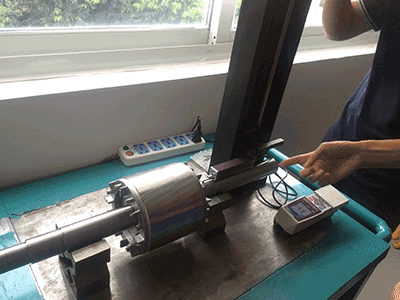

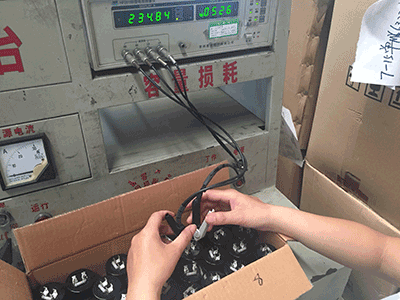

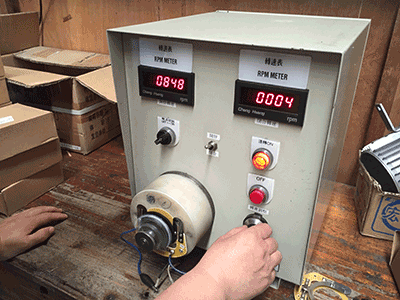

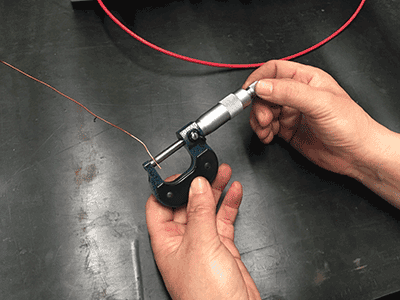

检验

看看我们的客户怎么说

惠丰是不同的。他真的知道我们需要什么,完全按照我们的需求来设计电机并且解决我们的疑惑。

某世界前十电机公司首席工程师

我们已经和惠丰合作了很多年,惠丰的电机从来都没有质量问题。

某全球风机制造商采购经理

我的一个客人告诉我,他20年前和我们买了一台惠丰生产的电机,现在这台电机仍然在运转!

某顶级减速机公司CEO

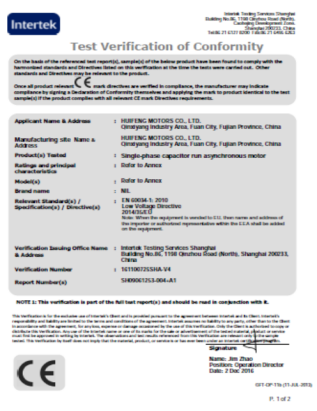

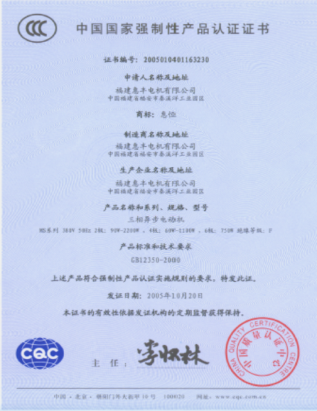

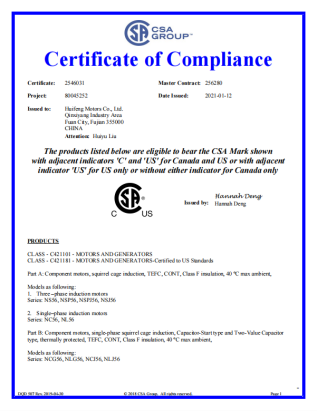

欧美多项权威联合验证,使用更安全更放心

我们的电机符合全球最高的安全和质量标准,证书由顶级的认证机构出具,例如Intertek,TUV,CQC...

这些顶级机构每年进行严格的非预先通知的工厂检验-每年多达4次,这样才能让工厂以最真实的生产状态接受检验,不是所有工厂都能通过检验。

这能保证我们的产品永远真正按照这些标准进行生产,从而保证产品的安全和性能。

CE(Intertek)

CCC(CQC)

CSA(CSA Group)

ISO9001

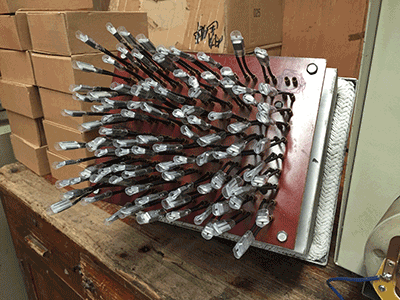

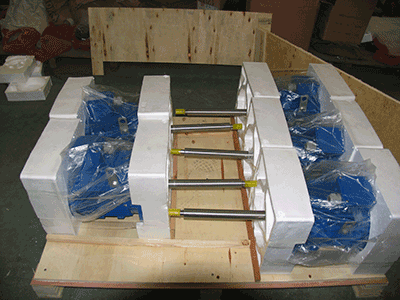

包装

我们有不同类型的空运和海运包裹。

发货

联系我们

As a professional stainless steel washdown electric motor manufacturer in China, We have been in the electric motor industry for over 30 years.

无论您需要:

交流电机或永磁电机

数控加工服务或定转子冲片

高速永磁风机

标准电机或定制电机

只需联系我们,惠丰总能满足您不同的需求。